Hydrophilic Fumed silica

Technical Data

| PROPERTIES | UNIT | SPECIFICATION | TYPICAL VALUE |

|---|---|---|---|

| pH | - | 3.9-4.5 | 4.13 |

| Ignition Loss, 1000℃ | % | 2max | 0.61 |

| Moisture Loss at 105℃, 2 hour | % | 2max | 0.64 |

| Purity | wt% | 99.8min | 99.85 |

| Carbon | % | 0.2max | 0.02 |

| Chloride (Cl) | ppm | 250 | 34 |

Products Description

CAS number: 7631-86-9

Chemical name: fumed silica, silicon dioxide

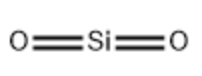

Molecular Formula:

Melting point: 1700°C

Boiling point: 2300°C

Density: 2.2 g/mL at 25°C

Hydrophilic fumed silica with a specific surface:

150㎡ /g.

200㎡ /g.

300㎡ /g.

380㎡/g.

Applications

(1) Fumed silica is mainly used in sealants, paints, coatings and some other polymers such as rubbers, plastics and resins to act as a reinforcement, thickening, anti-setting and rheology agent.

(2) Used as a free flow aids in the powder system such as food, pharmacy, fertilizer and extinguisher etc.

(3) Used as additives in cosmetics, defoamers, batteries, thermal insulation materials etc.

(4) Fumed Silica is a good matting agent to migrate to the surface of the paint film during the film formation process, which can produce the expected roughness on the surface of the paint film and significantly reduce the surface gloss.

(5) Fumed silica also good anti-abrasion agent the surface-treated with methacryl silane and can be added to the polyurethane coating to provide a friction-resistant effect.

(6) Fumed silica improves the weather ability and scratch resistance of the coating and improves the bonding strength between the coating and the substrate. At the same time, fumed silica has strong ultraviolet absorption and infrared light reflection properties, and it can improve the anti-aging property of the coating by adding it to the coating.

Packing

10KGS/Bag. 200KGS/Pallet. 2000KGS/20'P

10KGS/Bag. 400/KGS/Pallet. 4000KGS/40'GP

10KGS/Bag. 420KGS/Pallet. 4200KGS/40'HQ

Leave a message